Preparing for Trump-Era Tariffs: Strategies to Safeguard Global Supply Chains

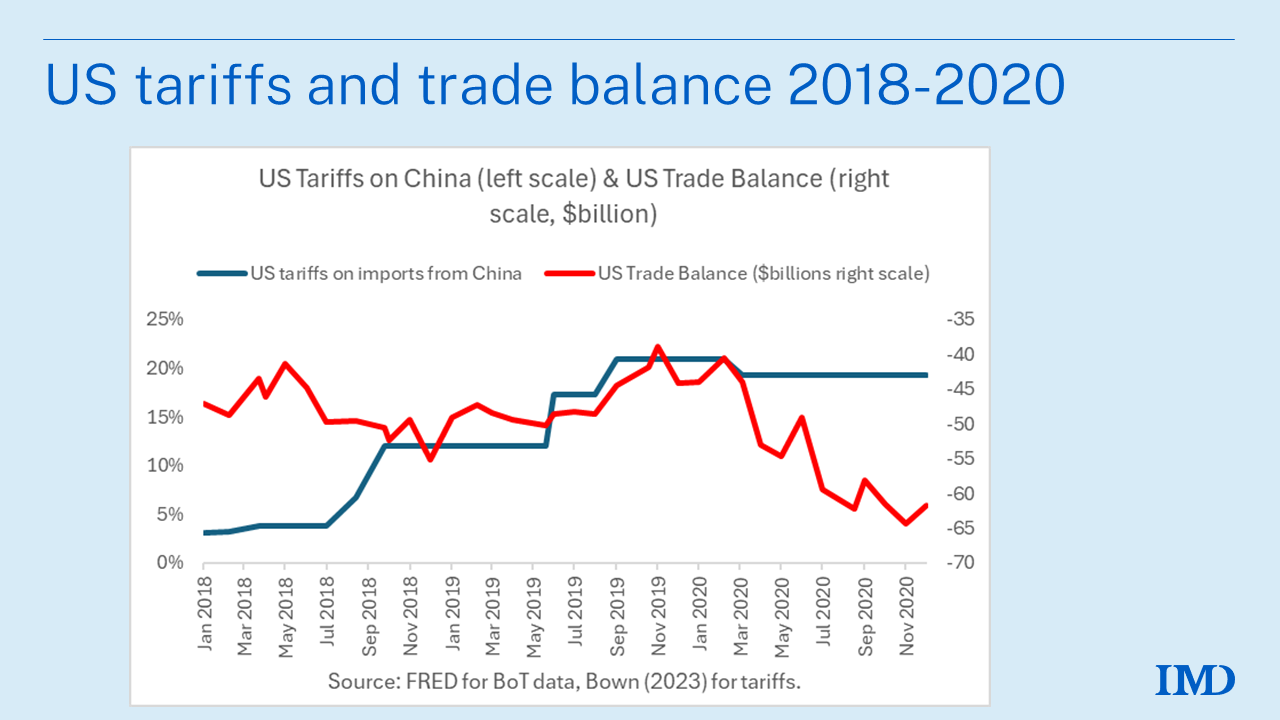

As the possibility of renewed Trump-era tariffs looms, industries are already planning how to protect their supply chains from potential disruptions. President-Elect Donald Trump has proposed imposing blanket tariffs of up to 20% on all imports, and even higher tariffs—ranging from 60% to 100%—on goods from China.

John Donigian, Senior Director of Supply Chain Strategy at Moody’s, cautions that the U.S. could return to its previous approach to tariffs, leading to higher duties on imports from major manufacturing nations. This shift would complicate already strained global supply chains, further challenged by post-pandemic recovery and rising geopolitical tensions.

Sector-Specific Impact of Tariffs

Donigian points out several industries that are most likely to feel the brunt of these potential tariffs:

- Electronics & Technology: Complex and fragmented supply chains could make shifting production costly and time-consuming.

- Automotive: Manufacturers reliant on international parts suppliers may face higher costs and longer lead times.

- Retail & Consumer Goods: Increased tariffs could push up consumer prices and create inventory shortages.

- Pharmaceuticals & Medical Devices: Moving production could introduce regulatory hurdles and quality control challenges.

As a result, companies in these sectors may need to rethink their sourcing and manufacturing strategies, potentially relocating production closer to North America or even bringing manufacturing back to the U.S.

Strategies for Mitigating Tariff Impact

To reduce the potential damage of these tariffs, Donigian outlines several approaches:

- Supplier Diversification: Expand sourcing across multiple regions to decrease reliance on any single market.

- Dual Sourcing: Utilize multiple suppliers for critical components to reduce risks associated with supply chain disruptions.

- Strategic Inventory: Build up stockpiles to cushion the impact of delays and disruptions in the supply chain.

He also suggests taking advantage of free trade zones, bonded warehouses, and duty drawback programs to minimize the financial impact of tariffs. For those considering reshoring, investments in automation and advanced manufacturing technologies can help offset the higher cost of labor.

The Importance of Cross-Functional Coordination

As businesses prepare for these changes, Donigian emphasizes the need for cross-departmental coordination. Aligning procurement, logistics, and risk management teams will be crucial to adapting swiftly to new trade policies and minimizing disruptions to the supply chain.

Shifting Global Manufacturing and Distribution

In response to the anticipated tariff increases, many companies will reassess their global manufacturing and distribution networks. Those who diversify their supply sources, consider reshoring, and adopt new technologies will be best positioned to handle the evolving trade landscape.

Get actionable advice on cost-saving strategies that boost your bottom line.

Subscribe here: